A Day in the Life of a Chocolate Manufacturer

May 17, 2016

In a nation-wide survey conducted last October, it was found that Singaporeans perceive the food manufacturing sector as a labour-intensive, low-tech and low-value sunset industry. To test this common perception, I went behind-the scenes in one of our home-grown food factories, where I experienced a day in the life of a food manufacturer and learned about each step of the production process along the way.

Taking You Behind the Scenes of Aalst Chocolate Factory

Did you know that Singapore has its own chocolate manufacturer? Aalst Chocolate produces chocolates and exports 98% of its products to over 45 countries all over the world.

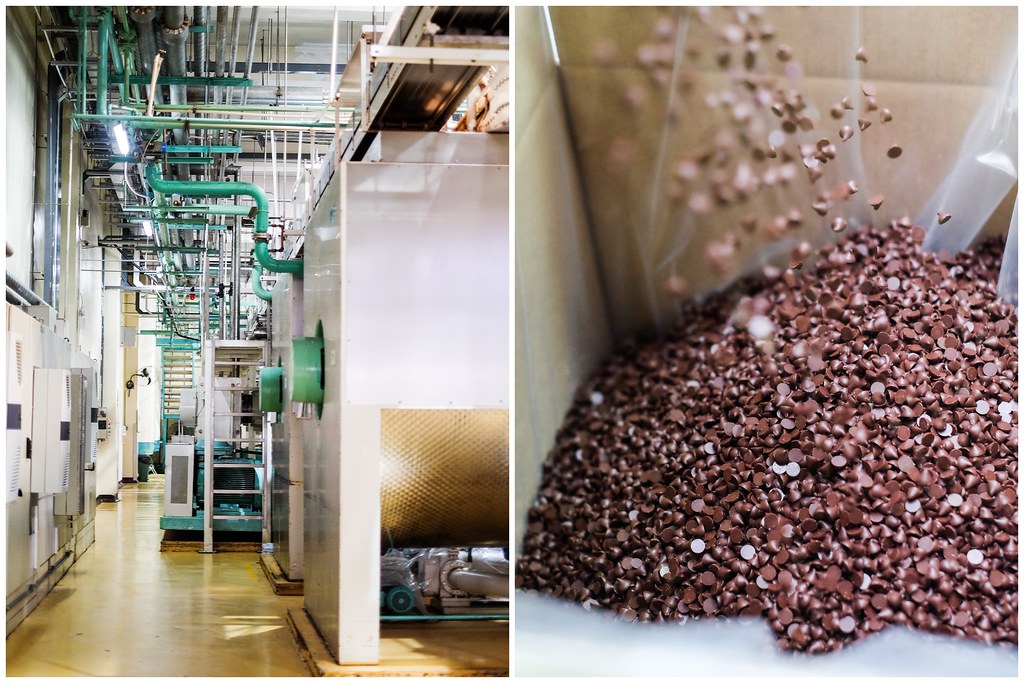

If you saw the movie Willy Wonka & the Chocolate Factory and imagined a chocolate factory that includes a chocolate river, then you are very wrong! What met my eyes was state-of-the-art automation that could do all the manual work: roasting, blending, refining, conching. One example is the cocoa press – a hydraulic press that squeezes out cocoa butter and leaves behind a fine cocoa powder.

In addition, the making of chocolate chips now follows an efficient assembly line. With these advances, chocolate can be produced on a huge commercial scale. This has made chocolate the easily available and affordable snack that it is today!

An interesting highlight of the process was ‘conching’. During conching, chocolate is stirred back and forth continuously, smoothening the chocolate and rounding out the flavour. Before this process, chocolates are usually coarse. But with the help of conching, the flavour, aroma, texture and overall quality of the chocolate is enhanced.

After conching and cooling down, we come to the next step – ‘tempering’. Tempering is the process of bringing the chocolate to a certain temperature. Ever noticed that glossy shine on your high quality chocolate? Proper tempering produces this smooth finish and that crisp ‘snap’ when you bite into the chocolate. In the past, chocolatiers had to temper by hand using the seeding method. This requires experience with handling an offset and a triangular spatula, simultaneously. Also, one has to work quickly with the chocolate in order to achieve successful tabling. Manual tempering can be very tedious and time consuming.

Next up is the ‘moulding’ process. Here, chocolate is poured into moulds to obtain a chocolate ‘shell’. This is filled with unique fillings, such as hazelnut praline used in the typical Belgian-style pralines.

Thankfully, with the help of innovation, there is now a tempering and filling machine that can save you the effort for tempering and moulding. Imagine having to fill the chocolate moulds one by one by hand – how time and energy consuming that would be! But with the new technology, it is so much simpler, quicker and consistent.

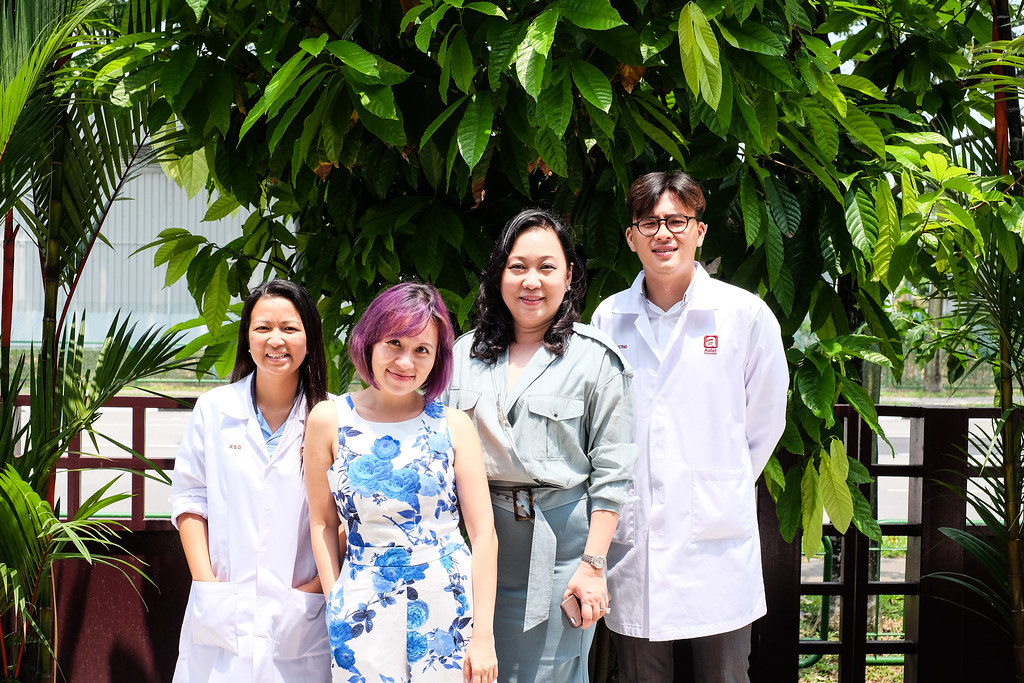

Finally, I had the chance to make my own chocolate! I met the talented young chefs, Chef Stanley and Ian, who taught me how to make chocolates with raspberry glaze. They shared how automation has enhanced the consistency of the chocolates and minimised the need for handling. This leaves them with more time and energy for experimenting with new products! That’s right – besides production, food manufacturing also involves developing new products. For example, Aalst Chocholate also makes their own premium Louella chocolates. Yum Yum!

I’ve always thought that working in a factory means long hours and boring manual labour. But after this eye-opening experience, I realised that automation is shaping the food manufacturing sector, promising so many interesting opportunities for creativity!

Wouldn’t it be wonderful to create your own food, and produce it not just for Singaporeans to enjoy, but for the rest of the world too? Foodies out there – the next time you think of starting an F&B outlet, how about considering joining a food factory instead?

Thank you to the Aalst Chocolate team for the kind hospitality!

About SG Food Makers

SG Food Makers is a project led by the Singapore Food Manufacturers’ Association (SFMA), to enhance Singaporeans’ perception of the local food manufacturing sector, with the goal of encouraging more Singaporeans who have a passion for food to consider a career in this promising sector.

Check out their Instagram @SgFoodMakers to understand more about the manufacturing sector.

This post is brought to you by Singapore Food Manufacturers’ Association.